SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Part Number:G130097(Mounting Band P013722,Cover Assembly P538259,Clip P776033) Part Type:Air Filter Assembly Brand:Donaldson Replacement MOQ:20pcs

Part Number:TM720D-400 Part Type:Reverse Osmosis Element Brand:Toray Replacement MOQ:60pcs

Part Number:03254375 Part Type:Cabin Air Filter Brand:Manitowoc Replacement MOQ:20pcs

Part Number:6B924 Part Type:Pleated Air Filter MERV Rating:8 Brand:Air Handler Replacement MOQ:20pcs

Part Number:P923075 Part Type:Breather Filter Brand:Donaldson Replacement MOQ:20pcs

Part Type:Water Absorbing ST Filter Brand:Donaldson Replacement MOQ:60pcs

Fuel Filter Manufacturer & Supplier from China OEM & ODM • Spin-on & Inline Fuel Filters • MOQ 60 pcs Filters King is a professional manufacturer and supplier of high-quality fuel filters from China. We specialize in OEM & ODM services, offering spin-on, inline, and fuel water separator filters with low MOQ and worldwide shipping. Find the perfect filter for your equipment and ensure reliable engine performance. Fuel Filter Key Features Our fuel filters are designed to deliver high performance, long-lasting durability, and reliable protection for your engines. Explore the key features that make our filters compatible with top brands and ideal for a wide range of applications. Icon Feature Description Wide Compatibility Compatible with Baldwin, Donaldson, Fleetguard, Mann, Parker, Wix, and more. Premium Material ISO-certified materials, heat-resistant and corrosion-resistant for long life. High Efficiency Precision filter design extends engine life and reduces failure rates. Fast Delivery Global shipping with low MOQ of 60 pcs, ideal for wholesalers and retailers. Explore Fuel Filter Types Spin-on Fuel Filter Easy to replace whole cartridge, ideal for cars, trucks, and machinery. Inline Fuel Filter Installed in fuel line, compact design suitable for motorcycles and small engines. Fuel Water Separator Separates water and contaminants from diesel fuel to protect engines. Request Quote Cartridge Fuel Filter Replaceable filter element with fixed housing, suitable for heavy machinery. Applications of Fuel Filters Our fuel filters are trusted in multiple industries to ensure clean fuel delivery, prevent engine damage, and extend equipment life. Explore the key applications below: Automotive & Trucks Protects passenger cars, commercial vehicles, and trucks by ensuring clean fuel injection and engine efficiency. Construction Machinery Used in excavators, loaders, bulldozers, and other heavy equipment to prevent costly downtime. Agricultural Equipment Reliable filtration for tractors, harvesters, and farming machinery, ensuring smooth operation in tough conditions. Marine Engines Specialized filters to separate water from fuel, protecting boat and ship engines from corrosion and failure. Generators & Industrial Engines Ensures stable power supply by keeping diesel generators and industrial engines free from contaminants. Contact Us Looking for high-quality fuel filters or need a custom solution? Get in touch with our team today. We are ready to support your business with reliable products and fast service. CHINA EVERLASTING PARTS CO., LIMITED WhatsApp/Wechat: +86 18965520297 WhatsApp/Wechat: +86 18144082725 Email: Sales@filters-king.com Website: www.filters-king.com

2024-04-02

2024-04-02Introducing the 1013032300 Oil Filter For Weichai generator - the ultimate solution to maintain the optimum performance of your prized Weichai diesel generator. Crafted with precision and unparalleled quality, this oil filter guarantees a level of protection that is second to none. Engineered to perfection, the 1013032300 oil filter ensures that your Weichai generator operates at its peak efficiency. It provides superior filtration, effectively removing impurities and contaminants from the oil, ensuring smooth operation and longevity of your generator. Unmatched in quality, this oil filter is manufactured with the highest standards in mind. Each component is carefully selected and combined to create a product that performs flawlessly under even the most demanding conditions. Designed to be a perfect fit for Weichai generators, the 1013032300 oil filter is easy to install, saving you time and effort. With its proven effectiveness, you can have peace of mind knowing that your generator is safeguarded against any potential damage. What sets the 1013032300 oil filter apart is not only its top-notch quality but also its competitive price. We understand the importance of value for money, and that's why we offer this exceptional filter at a price that won't break the bank. Now you can protect your Weichai generator without compromising your budget. As a direct product from our esteemed China filter factory, you can trust in the reliability and authenticity of the 1013032300 oil filter. We take pride in our commitment to delivering only the best products, and this filter is no exception. Invest in the 1013032300 Oil Filter For Weichai generator and experience the difference it makes in enhancing the performance, longevity, and efficiency of your Weichai diesel generator. Don't settle for anything less when it comes to protecting your investment. Choose the best, choose the 1013032300 oil filter. Any need please contact with us WhatsApp: +86 18965520297 Email: Sales@filters-king.com

2022-07-23

2022-07-23Fuel Filter AR86745 FF5051 FF236 AR86755 FF203 11-7264 11-6285 Fleetguard FF5051 HIFI SN5051,Baldwin BF855,CAT 3I1225,Donaldson P550955,Fram P3768,Luberfiner LFF1005,Napa 3130,Onan 149-1758,Purolator F53193,Wix 33130 Fleetguard FF236 HIFI SN1236,Baldwin BF806,Caterpillar 9Y-4416,Donaldson P550888,P552387,P779307,Fram P3500,Luberfiner FP888,Napa 3063,Onan 149-2513,Purolator F50033,Wix 33063 John Deere AR86755 AC Delco TP1049,HIFI SN1205,Agco 71367686,Baldwin BF912,Case IHC 548348C1,548348-C1,Caterpillar 3I1412,6N-7617,8N-9803,9Y-4445,Donaldson FFP559803,P559803,Fleetguard FS1205,Fram PS3602 PS3607,Luberfiner LFF1131,Mann 6670055100 WK13002,Massey Ferguson 1048547M91 1048547-M91,Napa 3369,Wix 33369,Woodgate WGFS1205 Fleetguard FF203 Baldwin BF909,Case IHC 1959802C1 1959802-C1,Caterpillar 3I1233 3I-1233 9Y4423,Donaldson FFP551130 P551130 P779297,Fram P1130 P1130A,Hengst H162WK,Hifi SN203,Ingersoll Rand 35308048,John Deere AR50041 AR50141 R16951,Kohler 223414,Kubota 7000014663 70000-14663,Mann 6670355100 WK13001,Napa 3370,Onan 1491754 149-1754,Purolator F50147 F53156 P147 PFC3156,Renault 6005009417,Sofima S4328NC SFFF8786,Wix 33370,33370MP,Woodgate WGF203 Thermoking 11-7264 Baldwin 50005306,BF7580,Donaldson P557264,Fleetguard FF5275,Fram PA7569A,PS7569,PS7569A,PS7576,Luberfiner L7264F,L7264F1,L7264F-1,Napa 3543,Stanadyne 31756,Thermoking 117264,11-7264,127264,12-7264,NOV64,Wix33543,Woodgate WGF5275 Thermoking 11-6285 Baldwin BF7579,Donaldson P556285,Fleetguard FF5276,Fleetrite FFR85276,Fram P7678, P7678A,Kralinator F3544,Luberfiner L6285F,L6285F1,L6285F-1,Napa 3544 Purolator F55188,SF Schupp SK 3637,SK3637,Thermoking 116285,11-6285,126285,12-6285,NOV85, Wix 33544,Woodgate WGF5276 John Deere AR86745 AC Delco TP1149,Allis Chalmers 4036432,71367687,Baldwin BF959,Caterpillar 3I1343,Coopers Fiaam FEM4032,Donaldson FFP556745,P556745,Fiat 74036432,Fleetguard FF5045,Fleetrite FFR85045,Fram P3815,P3815A,Hengst H286WK,Ingersoll Rand 36889657, John Deere AR86745,R27091,RE10104,RE27091,RE57073,Kohler 223953,Kralinator F756,Luberfiner AF550,LFF1129,Mann 1021754S01,WK8106,Napa 3371,3375,Onan 1491802,149-1802,SF Schupp SK 3567,SK 3569/67,SK 356967,SK3567,SK3569/67,SK356967, Stanadyne 22072,22177,22221,24336,26583,26654,26663,26667,Timberjack 416257,841625700,TRP 1535404,Vapormatic VPD6023,Vauxhall GM 25012899,Wix 33371,33375,Woodgate WGF5045

2019-10-18

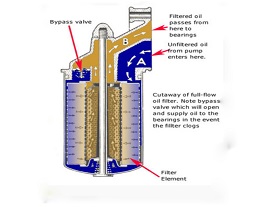

2019-10-18Engine oil plays a very important role in the engine. It helps to cool the engine by transferring heat. Sealing the gap between the piston ring and the cylinder wall; absorbing contaminants; and suspending soot particles as combustion residues. Contaminants can be organics such as fungi and bacteria in the air. Inorganic particles can be a lot of things, including dust that is drawn into the engine during operation. The outside of the oil filter is a metal can with a gasket that can be fastened to the mating surface of the engine. A gasket is attached to the base of the can and a hole is formed around the area inside the gasket. The center hole is threaded to mate with the oil filter assembly on the engine block. The inside of the jar is a filter material, the most common being synthetic fibers. The engine's oil pump moves the oil directly to the filter and then enters the oil filter from the hole in the perimeter of the base plate. Dirty oil passes through the filter media and then returns through the center hole where it re-enters the engine. Typically, filters have two media types: primary and secondary. The primary medium can block particles as small as 25-30 microns (human hair size is 65-70 microns) and the secondary medium can block particles as small as 5-10 microns. More filter cross reference you can get from www.filters-king.com.

2019-08-12

2019-08-121. Run the machine to warm up, stop and close the air outlet valve, and unscrew the fuel plug one turn to let the system relieve pressure. 2. Open the drain valve and drain the oil. After draining the oil, close the valve and transport the oil to the local waste oil treatment center. 3. Remove the oil filter. 4. Clean the oil filter holder, add lubricant to the gasket of the new oil filter, and tighten the oil filter by hand. 5. Remove the filler plug and refuel until the oil level reaches the plug. Retighten the filler plug. 6. Run the machine for a few minutes, stop, and wait a few minutes for the oil level to stabilize. Allow the system to relieve pressure by unscrewing the filler plug. Refuel until the oil level reaches the request and tighten the screw plug. More filter details from www.filters-king.com.

2020-06-08

2020-06-08Precautions 1. All protective covers must be covered before the filter is started. It is forbidden to open it by itself during operation. 2. Every time the machine is turned on, the bottom valve of the machine should be opened and drained cleanly. During the operation of the machine, the bottom valve of the machine should be drained once every 4 hours to ensure the drying inside the tank. 3. Before starting any maintenance and repair measures: Press the stop button, turn off the power, close the air outlet valve, and unscrew the fuel plug one turn to depressurize the compressor. 4. It is forbidden to adjust the pressure adjustment switch by yourself. 5. If the equipment is to be removed from the main power cord or reinstalled, the motor steering must be checked and operated in the direction indicated on the fuselage. 6. During the operation, it is found that there is a collision or other abnormal sound should be stopped immediately, and the machine can be started after the fault is eliminated. 7. When cleaning, it is strictly forbidden to rinse the equipment directly with water, paying special attention to avoid splashing water on the electric control box. 8. Oil specifications: Never mix oils of different brands or models. We are professional engine filter manufacturer, get more Oil Filters, Air Filters, and filter assembly from www.filters-king.com.

2019-08-03

2019-08-03Engine air filters are developed based on filter performance requirements, vehicle operating environment, available space, filter media characteristics and production techniques. The design process includes analytical theory and empirical models describing the filter media properties and aerosol flow in the filter housing as well as the filter elements. Filter media carefully based on these models and simplified laboratory testing. The filter design was evaluated in great detail through a series of laboratory and field experiments. The role of the engine intake system has increased due to engine exhaust particulates and evaporative emission regulations. Engine life, engine emissions and fuel consumption depend on the design of the intake system and its performance. Providing an optimized solution to these requirements determines the trend of the filter. This has driven the need for smaller, more compact filters and more efficient permeability filter media. The efficiency can be significantly improved by applying a layer of nanofibers to the cellulose or synthetic substrate. The ISO fractional efficiency test method, in its final development stage, clearly shows the advantages of nanofiber filter media. The ISO fractional efficiency test method, in its final development stage, clearly shows the advantages of nanofiber filter media.

2019-07-26

2019-07-26The structure of the filter material can be divided into two types: surface type and depth type. (1) surface type The surface type filter material is a fine filter mesh woven with a wire, and is also used in other forms such as wire winding. The filtration accuracy is determined by the size of the woven holes or the size of the wire gap. Any particles larger than the size or clearance of the aperture can not pass through just the ideal state, which is not practical in practice. The woven filter or wire is wound into a filter element having the same size of pores, and its filtering action only occurs on the surface of the filter screen, so it is called surface type filtration. As the dirt accumulates on the surface of the screen, its pores are constantly blocked, so that the pressure drop is gradually increased; the filtration efficiency is also lowered because the particles trapped in the mesh may be squeezed out of the mesh at any time. If it is desired to control the pressure drop within a certain range, the filter element should have a sufficiently large filtration area. This filter element can be reused after cleaning. (2) Deep filter media The deep filter media is made of fiber papermaking and has a certain thickness of filter media. The properties of this filter are quite different from those of surface type filtration. Its shape of the eyelet, the size is irregular, uneven, and the inner part is complicated by bending and twisting. Its filtering effect occurs not only on the surface of the filter medium but also in the depth of the filter medium, so it is called depth type filtration. Since the filter medium has a certain thickness and the passage is in all directions, its dirt holding capacity is much larger than that of the surface type filter, and the pressure drop is also much lower than that of the surface type filter. In addition, because of its wide range of pore size distribution, it can also filter out a large number of fine particles. For the depth filter, the fiber diameter constituting the filter medium has a direct influence on the filtration efficiency and other properties. A filter layer made of a relatively small diameter fiber can form more through holes in a unit area, and can also form more channels in the interior. Therefore, its filtration efficiency and dirt holding capacity are higher than those of the coarser fiber. For the same reason, its pressure drop is also smaller than the latter. Therefore, the filter element made of fine fiber has a long working life.

2019-07-12

2019-07-12One: start inspection and preparation 1: Before using the water separator equipment, the driver's consent should be obtained. 2: Check the line installation of the fuel water separator, whether the steering of the supporting pump is normal 3: Water is supplied to the fuel water separator, and the top air valve is opened to allow air to escape. 4: Check the oil and water separation in the marrow water inlet and outlet system without any leakage Two: precautions during operation 1: Adjust the drain valve opening degree and keep the pressure inside the separator to facilitate the elimination of the oil in the separator. 2: Observe whether the gauges such as pressure gauges and thermometers are normal. 3: Observe the working condition of the treated drainage water quality and oil concentration alarm 4: After the discharge is over, it should continue to be poured into clean water for 15 minutes to clean the separator. 5: Close the inlet and outlet after the pump is stopped, avoid the loss of clean water in the cylinder, reduce the oxidation and corrosion of the inner wall. 6: Each time the fuel water separator is used for discharge, it should be recorded in the oil beauty record book. Three: maintenance 1: Regularly clean the filter, open the bottom of the separator to vent, and remove the sediment deposited in the lower part, impurities 2: Clean the internal separation components of the separator in time, and avoid cleaning the inner wall and components of the separator with a cleaning agent. 3: When a fault occurs, the cause should be identified and the failed coalescing component should be replaced in time.