About Us

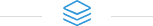

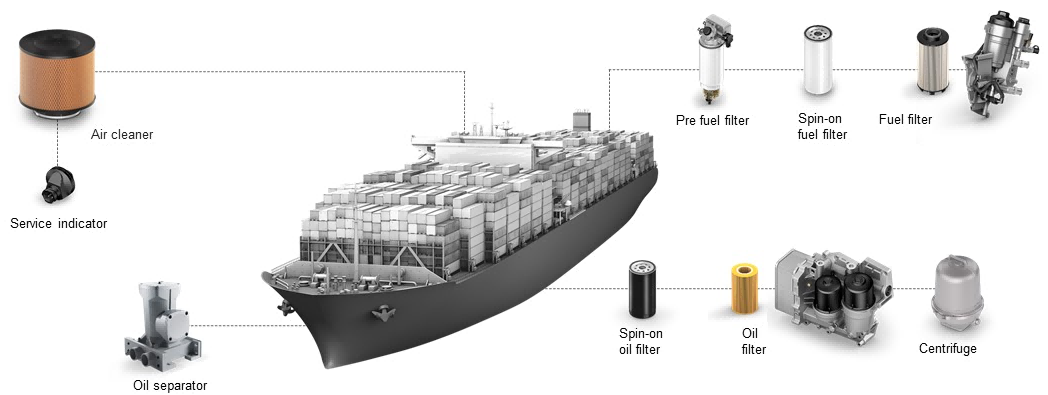

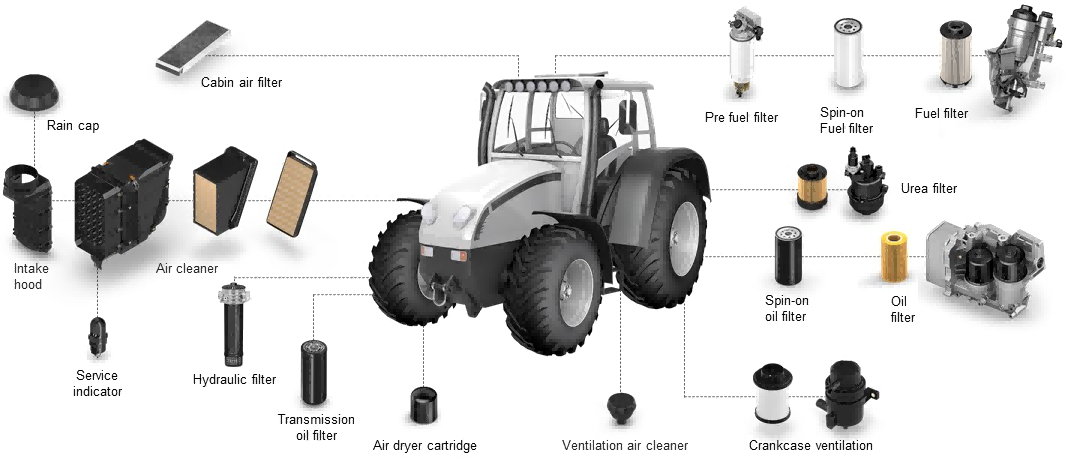

About China Everlasting Parts – Your Premier Heavy-Duty Filter Manufacturer & Supplier Since 2008 Company profile Our company is specialized in the production of various heavy duty oil filters, cabin air filter ,fuel filters and fuel water separator and other genuine filter replacement parts. We have our own filters factory and our own brand AYREST,with 17 years filters produce experience. Meanwhile have build Good Cooperation relation with more than 20 professional manufactures, that can ensure supply steady quality filters to customers. We are filtration specialists and have mastered the techniques of separation and filtration processes. We own Complete testing equipment ensure supply acceptable quality filters to users. Our filters technology, material and quality refer to the original standard. Example: our cat filters replacement with technology is ""Non-Metallic Center Tube;Spiral Roving;Molded End Caps". Our products Our filters are widely applied across construction, agriculture, transportation, industrial, and marine equipment, and are compatible with many world-renowned OEM brands. Construction & Earthmoving Equipment Excavators, bulldozers, wheel loaders, cranes, articulated trucks, compactors, pipelayers Compatible brands include: Caterpillar, Komatsu, Hitachi, JCB, Hyundai, Doosan (Daewoo), Kobelco, Volvo Construction Equipment, John Deere, CNH, Rexroth Agricultural Machinery Agricultural tractors, harvesters, agricultural equipment Compatible brands include: John Deere, CNH, Yanmar, Hino, Mitsubishi, Kubota (optional), Perkins Commercial Vehicles & Transportation Trucks, buses, coaches, highway trucks Compatible brands include: Mercedes-Benz, IVECO, Scania, DAF, Volvo Trucks, Hino, Nissan Engine & Power Generation Systems Generator sets, diesel engines, power units Compatible brands include: Perkins, Deutz, FG Wilson, Lister Petter, MTU, Mitsubishi, Yanmar Industrial & Air Compressor Equipment Air compressors, industrial machinery Compatible brands include: Atlas Copco, Ingersoll Rand, Parker Racor, Mann, Hengst Hydraulic Systems & Industrial Filtration Hydraulic systems, industrial equipment Compatible brands include: Hydac, Pall, Rexroth, Parker Marine Equipment Steamships, marine engines, marine power systems Compatible brands include: MTU, Volvo Penta, Perkins, Deutz Aftermarket & Filter Brand Cross References Replacement and aftermarket filtration Compatible with filter brands such as: Fleetguard, Donaldson, Baldwin, Wix, Luber-Finer, Mann, Hengst Services EVERLSTING PARTS COMPANY is at your disposal throughout the year, in order to help you make the best choice in filtration for your equipment. The Influence and Strength of the Specialist in Filtration : The most complete range of filters in the world: 20000 available references in stock, Around 3000,000 Pcs products in stock, 10000 Square meter warehouse. Genuine quality standard can protect your engine well. Our brands: AYREST, 3 packing lines,can be customized Packaging. Multilingual, Multiple communication tools to respond to the worldwide requests 6*12H manager service. 17 Year filters export experience.

About Us

About Us

2026-02-04

2026-02-04

2026-01-23

2026-01-23

2026-01-09

2026-01-09

2025-12-31

2025-12-31

2024-07-07

2024-07-07

2024-06-24

2024-06-24

2024-06-16

2024-06-16

2024-06-07

2024-06-07