SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Part Number:G130097(Mounting Band P013722,Cover Assembly P538259,Clip P776033) Part Type:Air Filter Assembly Brand:Donaldson Replacement MOQ:20pcs

Part Number:TM720D-400 Part Type:Reverse Osmosis Element Brand:Toray Replacement MOQ:60pcs

Part Number:03254375 Part Type:Cabin Air Filter Brand:Manitowoc Replacement MOQ:20pcs

Part Number:6B924 Part Type:Pleated Air Filter MERV Rating:8 Brand:Air Handler Replacement MOQ:20pcs

Part Number:P923075 Part Type:Breather Filter Brand:Donaldson Replacement MOQ:20pcs

Part Type:Water Absorbing ST Filter Brand:Donaldson Replacement MOQ:60pcs

Fuel Filter Manufacturer & Supplier from China OEM & ODM • Spin-on & Inline Fuel Filters • MOQ 60 pcs Filters King is a professional manufacturer and supplier of high-quality fuel filters from China. We specialize in OEM & ODM services, offering spin-on, inline, and fuel water separator filters with low MOQ and worldwide shipping. Find the perfect filter for your equipment and ensure reliable engine performance. Fuel Filter Key Features Our fuel filters are designed to deliver high performance, long-lasting durability, and reliable protection for your engines. Explore the key features that make our filters compatible with top brands and ideal for a wide range of applications. Icon Feature Description Wide Compatibility Compatible with Baldwin, Donaldson, Fleetguard, Mann, Parker, Wix, and more. Premium Material ISO-certified materials, heat-resistant and corrosion-resistant for long life. High Efficiency Precision filter design extends engine life and reduces failure rates. Fast Delivery Global shipping with low MOQ of 60 pcs, ideal for wholesalers and retailers. Explore Fuel Filter Types Spin-on Fuel Filter Easy to replace whole cartridge, ideal for cars, trucks, and machinery. Inline Fuel Filter Installed in fuel line, compact design suitable for motorcycles and small engines. Fuel Water Separator Separates water and contaminants from diesel fuel to protect engines. Request Quote Cartridge Fuel Filter Replaceable filter element with fixed housing, suitable for heavy machinery. Applications of Fuel Filters Our fuel filters are trusted in multiple industries to ensure clean fuel delivery, prevent engine damage, and extend equipment life. Explore the key applications below: Automotive & Trucks Protects passenger cars, commercial vehicles, and trucks by ensuring clean fuel injection and engine efficiency. Construction Machinery Used in excavators, loaders, bulldozers, and other heavy equipment to prevent costly downtime. Agricultural Equipment Reliable filtration for tractors, harvesters, and farming machinery, ensuring smooth operation in tough conditions. Marine Engines Specialized filters to separate water from fuel, protecting boat and ship engines from corrosion and failure. Generators & Industrial Engines Ensures stable power supply by keeping diesel generators and industrial engines free from contaminants. Contact Us Looking for high-quality fuel filters or need a custom solution? Get in touch with our team today. We are ready to support your business with reliable products and fast service. CHINA EVERLASTING PARTS CO., LIMITED WhatsApp/Wechat: +86 18965520297 WhatsApp/Wechat: +86 18144082725 Email: Sales@filters-king.com Website: www.filters-king.com

2024-07-07

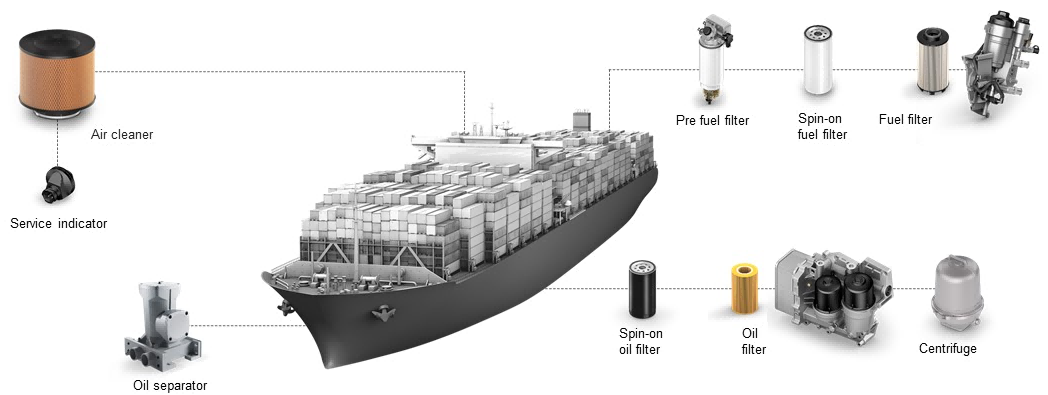

2024-07-07Marine Engine Filters: Comprehensive Protection for Your Vessel's Heart CHINA EVERLASTING PARTS CO., LIMITED - Your dedicated partner for professional marine filters, ensuring the optimal performance and longevity of your marine engines. Our Range of Marine Engine Filters Air Cleaner: Ensures clean air intake, vital for combustion efficiency and engine health. Oil Separator: Removes contaminants from oil, protecting critical engine components. Pre Fuel Filter: Provides initial filtration of fuel, preventing damage from contaminants. Spin On Fuel Filter: A convenient, high-efficiency fuel filter that simplifies maintenance. Fuel Filter Element: The core component for clean fuel supply, prolonging engine life. Spin-On Oil Filter: Easy to replace, providing clear oil for smooth engine operation. Oil Filter Element: Designed for thorough oil filtration, reducing wear and tear. Centrifuge: Advanced separation technology for clean fuel and oil. Compatible with Famous Marine Engines Our filters are compatible with a wide range of renowned marine engines, including: MTU Engines Cummins Engines Rolls-Royce Engines Caterpillar Engines Daewoo Engines Volvo Engines Deutz Engines MAN Engines Mitsubishi Engines Kubota Engines Why Choose CHINA EVERLASTING PARTS CO., LIMITED? Quality Assurance: We stand by the quality of our marine filters, ensuring they meet the highest industry standards. Comprehensive Range: Our diverse product line covers all your filtration needs for various marine engine types. Professional Service: With extensive knowledge and experience, we provide tailored solutions for your specific marine engine requirements. Global Reach: Our filters are trusted by marine professionals worldwide, reflecting our commitment to excellence. Contact Us For expert advice or to place an order, get in touch with our professional team through: WhatsApp/Wechat/Viber: +86 18965520297 Email: Sales@filters-king.com We are here to support your marine engine filtration needs, keeping your vessel's heart beating strong and clean.

2024-06-24

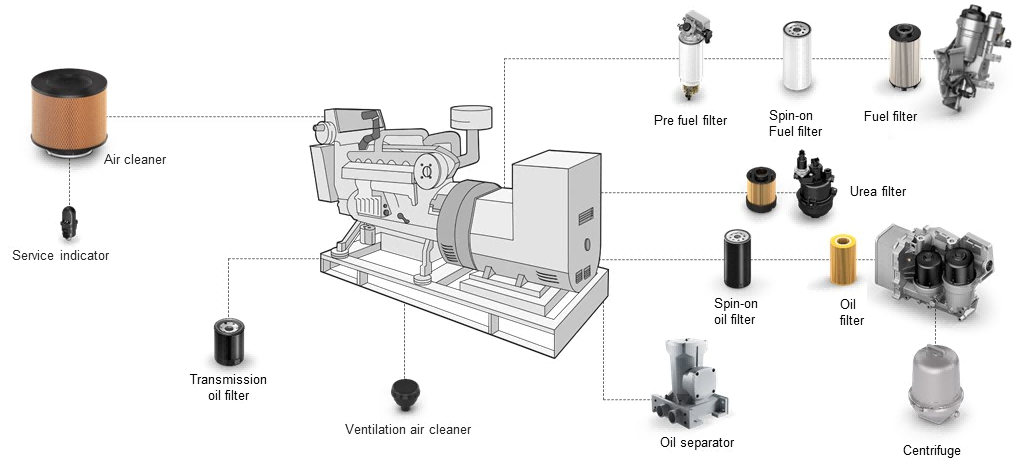

2024-06-24Ensuring Peak Generator Performance with Professional Filters Introduction: The unwavering performance of generators is paramount in providing reliable power solutions. Whether for backup power during outages or as the primary power source in mission-critical applications, the efficiency and longevity of these workhorses depend on the quality of their filtration systems. As a professional manufacturer and wholesaler of generator filters, we cater to a spectrum of renowned brands, ensuring their optimal operation with our comprehensive range of filters. Generator Brands We Serve: Our filters are compatible with a variety of leading generator brands, including KOHLER, Cummins, CAT, Mitsubishi, SDMO, JCB, MTU, Perkins, FG Wilson, Volvo, Weichai, and Yuchai. Our commitment to excellence ensures that our filters meet the high standards set by these industry leaders. Generator Filters We Offer: Our product line encompasses a wide array of generator filters designed to cater to different aspects of a generator's operation: Air Cleaner: The first line of defense against airborne contaminants, ensuring clean air intake for optimal combustion. Transmission Oil Filter: Protects transmission systems from wear by trapping harmful particles, ensuring smooth gear shifts and extended transmission life. Ventilation Air Cleaner: Maintains the integrity of the generator's ventilation system by preventing dust and debris from entering. Pre Fuel Filter: Filters out impurities before the fuel reaches the engine, safeguarding against potential damage and performance issues. Spin On Fuel Filter: Provides easy, efficient fuel filtration with a quick-change design that minimizes maintenance time. Fuel Filter Element: A critical component that ensures only clean fuel is supplied to the engine, enhancing performance and fuel efficiency. Urea Filter: Specifically designed for diesel exhaust fluid systems to ensure the purity of the urea solution used in emissions reduction. Spin On Oil Filter: Offers a convenient and effective solution for oil filtration, with a focus on ease of maintenance. Oil Filter Element: Essential for maintaining engine health by removing contaminants from the oil, prolonging engine life. Oil Separator: Efficiently separates oil from the exhaust gases, reducing emissions and protecting the environment. Centrifuge: Utilized for separating contaminants from liquids, particularly useful in maintaining the purity of lubricating oils. The Importance of Quality Generator Filters: Quality filters are indispensable for several reasons: Enhanced Performance: By ensuring clean fuel and oil, filters contribute to the generator's peak performance, providing stable power output. Extended Equipment Life: They protect the generator's components from wear and tear, delaying the need for costly repairs or replacements. Reduced Maintenance Costs: Regular use of quality filters can prevent more severe issues, reducing long-term maintenance expenses. Compliance with Emis...

2024-06-16

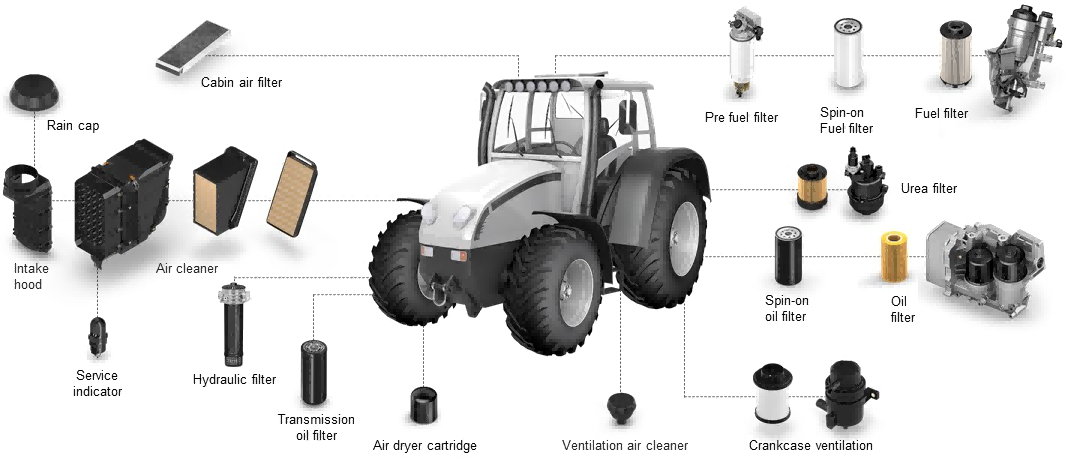

2024-06-16The Vanguard of Farming: Agricultural Tractor Filters for Unmatched Performance Introduction: The agricultural landscape is as diverse as the earth itself, and the heart of this vast panorama is the trusty agricultural tractor. Renowned brands like Mahindra, John Deere, Massey Ferguson, Case IH, Sonalika International, Escorts Group, Kubota, Deutz Fahr, and Claas have long been at the forefront of providing innovative solutions for the farming community. Central to the longevity and efficiency of these machines are the agricultural machinery filters that shield them from the rigors of the field. This article explores the critical role of these filters in maintaining peak tractor performance. The Agricultural Tractor Filter Spectrum: Agricultural machinery filters are the unsung heroes of farming equipment, working tirelessly to ensure that tractors perform at their best. Here's an overview of the types of filters that contribute to this performance: Cabin Air Filter: Ensures the operator's comfort by maintaining clean air within the cabin, free from dust and particulates that could affect visibility and health. Air Cleaner: Protects the engine from contaminants in the air that could lead to reduced efficiency and increased wear over time. Hydraulic Filter: Preserves the integrity of hydraulic systems by preventing the ingress of harmful particles that could damage pumps, valves, and actuators. Transmission Oil Filter: Aids in the smooth operation of transmissions by filtering out contaminants that could cause gear wear and reduce shifting efficiency. Air Dryer Cartridge: Eliminates moisture from compressed air systems, safeguarding against corrosion and potential system damage. Pre Fuel Filter: Acts as an initial barrier against impurities in the fuel before it enters the engine, protecting against performance-robbing deposits. Spin On Fuel Filter: Offers a convenient and efficient means of filtering fuel, with a quick-change design that minimizes downtime. Fuel Filter Element: Ensures that only clean fuel reaches the engine, optimizing combustion and fuel economy. Urea Filter: Specifically designed for tractors equipped with urea scrubbing systems to ensure the purity of the urea solution used to reduce emissions. Spin On Oil Filter: Provides easy maintenance with its spin-on design, guarding against leaks and facilitating faster oil changes. Oil Filter Element: A key component in maintaining engine health by trapping dirt and contaminants, ensuring clean oil circulation. Crankcase Filter: Maintains oil quality within the crankcase, promoting optimal engine lubrication and longevity. Ventilation Air Cleaner: Protects the engine from airborne contaminants that could be drawn into the ventilation system, preserving engine integrity. The Imperative of Filter Maintenance: Neglecting filter maintenance can lead to a cascade of issues, from reduced performance to costly repairs. Regular filter checks and replacements are essential for several reasons:...

2024-06-07

2024-06-07Introduction: Perkins generators are the backbone of power solutions for many industries, and ensuring their consistent operation involves regular maintenance and the use of high-quality components. One such component is the Perkins Generator Fuel Filter 5172762, designed not only for exceptional filtration but also with dimensions and weight optimized for ease of use and handling. This article delves into the specifics of the 5172762 fuel filter, its dimensions, and how it contributes to the maintenance of Perkins generators. The Dimensions and Weight of the 5172762 Fuel Filter: The Perkins Generator Fuel Filter 5172762 comes with specific dimensions that make it a perfect fit for Perkins generators while ensuring easy installation and replacement. Height (cm): 36.50 - The height of the filter is tailored to fit within the space constraints of Perkins generator systems, ensuring compatibility without compromising on filtration area. Outside Diameter (OD, cm): 19.50 - The outside diameter of the filter is designed to provide a balance between a large filtration surface area and the physical space available within the generator's fuel system. Weight: 2.500kg - The weight of the filter is a testament to its robust construction while remaining manageable for single-person handling during maintenance routines. Why These Dimensions Matter: The dimensions and weight of the 5172762 fuel filter are not just arbitrary numbers; they are the result of careful engineering to meet the needs of Perkins generator owners. Compatibility: The specific height and diameter ensure that the filter fits seamlessly into the Perkins generator's fuel system without any modifications, reducing installation time and potential errors. Ease of Maintenance: With a manageable weight of 2.500kg, the filter is easy to handle, reducing the risk of injury during replacement and improving overall maintenance efficiency. Optimized Performance: The dimensions allow for an optimal balance between the filter's size and its ability to perform efficient fuel filtration, ensuring that the generator operates with clean, uncontaminated fuel. The Role of the 5172762 Fuel Filter in Perkins Generators: Beyond its physical attributes, the 5172762 fuel filter plays a pivotal role in the maintenance and performance of Perkins generators. Contaminant Removal: It effectively removes harmful contaminants from fuel, safeguarding the engine from damage and wear. Fuel System Protection: By filtering out impurities, the fuel filter protects the fuel system components, including injectors and pumps, from premature failure. Extended Service Life: Regular use of the 5172762 fuel filter contributes to extending the service life of the generator, reducing long-term maintenance and replacement costs. Maintenance and Replacement: Understanding when and how to replace the 5172762 fuel filter is crucial for maintaining generator performance. Scheduled Replacement: Adhere to the recommended replacement schedule pr...

2024-06-07

2024-06-07Introduction: In the world of power generation, Perkins generators are renowned for their reliability and performance. However, even the most robust engines require vigilant maintenance to ensure their longevity. One critical component in this maintenance regimen is the oil filter. The 5381439 oil filter is a testament to quality engineering designed to protect your Perkins generator from the inside out. The Role of Oil Filters in Perkins Generators: Oil filters are often overlooked, yet they play a pivotal role in the health of any engine. For Perkins generators, the 5381439 oil filter is not just a replacement part; it's a guardian against various threats that can compromise engine performance. Removing Contaminants: The primary function of the 5381439 oil filter is to remove dirt, rust, metal particles, and other contaminants from the engine oil. This helps to maintain oil cleanliness and prevents these particles from causing wear and tear on engine components. Protecting Engine Components: By filtering out harmful particles, the 5381439 oil filter extends the life of engine components such as pistons, bearings, and valves, which are susceptible to damage from abrasive particles. Maintaining Oil Quality: Over time, engine oil can degrade due to heat and contamination. The 5381439 oil filter helps to maintain oil quality by trapping contaminants, ensuring that the oil continues to lubricate and protect engine parts effectively. Features of the 5381439 Oil Filter: The 5381439 oil filter is designed with several features that make it an essential component for any Perkins generator owner. High-Quality Construction: Made from durable materials, the 5381439 filter is built to withstand the rigors of continuous operation in a generator set. Advanced Filtration Media: The filter media within the 5381439 oil filter is engineered to provide high filtration efficiency, capturing even the smallest particles that can harm your Perkins generator. Compatibility: Specifically designed for Perkins generators, the 5381439 ensures a perfect fit and is guaranteed to meet the performance standards required for these engines. Easy Maintenance: With the 5381439 oil filter, maintaining your generator's oil system is straightforward. Its design allows for easy installation and removal, making routine maintenance a breeze. The Importance of Regular Oil Filter Replacement: While the 5381439 oil filter is built to last, it's crucial to replace it regularly to maintain optimal engine performance. Extended Engine Life: Regular oil filter changes using the 5381439 can significantly extend the life of your Perkins generator's engine by reducing the wear and tear on critical components. Improved Performance: A clean oil system allows your generator to run more efficiently, translating to improved performance and reliability. Prevention of System Failure: By capturing contaminants, the 5381439 oil filter helps prevent system failures that can result from clogged or contaminat...

2024-06-07

2024-06-07Introduction: In the realm of industry, the engine is the heart of power generation sets, air compressors, and various heavy machinery and agricultural equipment. High-quality engine oil is crucial for ensuring the long-term, stable operation of these mechanical workhorses. This article will delve into the specialized engine oils designed for industrial engines and how they serve as guardians of these mechanical hearts. The Importance of Engine Oil in Industrial Applications: Anti-Wear Protection: Industrial engines often operate under extreme loads, and high-quality engine oil provides the necessary lubrication to reduce component wear. Thermal Stability: In high-temperature environments, premium engine oil maintains stability to prevent engine damage from thermal degradation. Cleaning Performance: Sludge and carbon deposits generated during the operation of industrial machinery are effectively removed, keeping the engine clean. Anti-Corrosion Properties: Anti-corrosion additives in engine oil protect metal parts from corrosion due to environmental factors. Key Points for Choosing Industrial Engine Oil: Industrial Grade Performance: Opt for engine oils specifically designed for industrial engines, which typically have higher performance standards and stronger protective capabilities. High-Temperature Stability: Industrial environments experience significant temperature fluctuations, and engine oil must maintain performance at high temperatures. Longevity: Industrial equipment often runs continuously for extended periods, and choosing long-life engine oil can reduce maintenance frequency and extend oil change intervals. Compatibility: Ensure that the engine oil is compatible with existing oils in the equipment to avoid problems caused by mixing different oils. Engine Oil and Industrial Equipment Performance: Efficiency Improvement: Reduced internal friction and wear improve the mechanical work efficiency. Lower Operating Costs: By reducing maintenance and downtime, overall operating costs are lowered. Extended Equipment Life: Regular use of high-quality engine oil can significantly extend the service life of equipment. Enhanced Reliability: Ensures stable operation of equipment during crucial times, reducing the risk of unexpected downtime. Conclusion: Choosing the right engine oil is vital for industrial equipment such as power generation sets, air compressors, heavy machinery, and agricultural equipment. It not only provides comprehensive protection but also enhances equipment performance and reduces operating costs. Closing Thoughts: Selecting the right engine oil for your industrial equipment is like injecting stability and reliability into your business operations. Take action now to provide the most comprehensive and professional care for your equipment engines. For more information on industrial engine oils or professional equipment maintenance advice, please visit our website or ...

2024-06-07

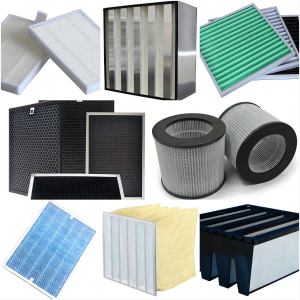

2024-06-07In today's world, the quality of air we breathe has a significant impact on our health. Whether it's at home, in the office, or in industrial environments, clean air is fundamental to a comfortable life and efficient work. Ventilation system filters play a crucial role in maintaining air cleanliness, and understanding them is essential. This article will guide you through the knowledge of ventilation system filters and how to choose the right one for your environment. **1. The Role of Ventilation System Filters** The primary function of ventilation system filters is to remove particles, dust, bacteria, and other pollutants from the air, providing clean and healthy air. They can filter out fine particles such as PM2.5 and PM10, reducing the spread of allergens and pathogens, which is especially important for asthma sufferers, those with allergies, and the elderly and children. **2. Different Types of Ventilation System Filters** There are various types of ventilation system filters available in the market, including: 1. **Pre-filters**: Capture larger particles such as dust and pollen. 2. **Medium-efficiency filters**: Can filter smaller particles suitable for environments that require cleaner air. 3. **High-efficiency particulate air (HEPA) filters**: Can filter out 99.97% of particles 0.3 microns and larger, making them the preferred choice for hospitals and laboratories with high air quality standards. 4. **Activated carbon filters**: In addition to filtering particles, they also adsorb harmful gases and odors. **3. Factors to Consider When Choosing a Ventilation System Filter** When selecting a ventilation system filter, consider the following factors: 1. **Filtering Efficiency**: Choose the appropriate filtration level based on the required air quality. 2. **Applicable Environment**: Consider whether the filter is suitable for your living or working environment. 3. **Maintenance Costs**: Opt for filters that are easy to clean and replace to reduce long-term maintenance costs. 4. **Energy Efficiency**: Choose filters with high energy efficiency to reduce energy consumption. With technological advancements, many filter manufacturers offer customized services to meet the specific needs of different environments. Whether it's special sizes, special filtration materials, or special functions, customized filters can provide a more precise solution for your needs. Choosing the right ventilation system filter not only improves air quality but also provides health protection for you and your family. When purchasing, always consider the filter's efficiency, applicable environment, and maintenance costs. Also, consider customized services to get the filter that best fits your needs. Fresh air is the cornerstone of a healthy life. By carefully selecting and maintaining ventilation system filters, we can create a more comfortable and healthy living and working environment. Let's start with breathing and enjoy the endless possibilities brought by fresh air...

2024-05-20

2024-05-20Introducing the Kalmar Equipment Filter – Your Reliable Solution for Optimal Performance When it comes to enhancing the efficiency and longevity of Kalmar terminal tractors, forklifts, empty container handlers, and reachstackers, there's one name you can trust: the Kalmar Equipment Filter. Expertly engineered to meet the rigorous demands of industrial settings, this top-of-the-line filter is designed to deliver unparalleled filtration performance. Unleash the Power of Superior Filtration At Kalmar, we understand the crucial role that clean and uncontaminated fluids play in the smooth operation of heavy machinery. That's why we have developed the Equipment Filter with utmost precision and attention to detail, ensuring that even the tiniest particles and impurities are effectively captured and eliminated. Rest assured that your equipment will remain free from harmful pollutants, enhancing its efficiency and extending its lifespan. Uncompromising Quality and Reliability Kalmar is renowned for its commitment to quality, and the Equipment Filter is no exception. Crafted from premium materials and utilizing state-of-the-art technology, this filter is built to withstand the harshest conditions and deliver consistent performance. Whether you're operating in dusty environments or tackling heavy-duty tasks, our Equipment Filter remains a trusted companion that never compromises on reliability. Effortless Installation and Maintenance Simplicity and convenience are key considerations in today's fast-paced industries, and the Kalmar Equipment Filter reflects this philosophy. With its user-friendly design, installing and maintaining the filter is a breeze. Save time and minimize downtime as our filter seamlessly integrates into your existing equipment system, enabling you to focus on what truly matters – maximizing productivity. Unmatched Compatibility Embracing versatility, the Kalmar Equipment Filter is specifically engineered to perfectly fit Kalmar terminal tractors, forklifts, empty container handlers, and reachstackers. With its precise specifications and tailored compatibility, our filter effortlessly integrates into your machinery, ensuring a seamless and efficient filtration process. Invest in Excellence By opting for the Kalmar Equipment Filter, you're making a wise investment in the long-term performance and reliability of your Kalmar equipment. Choose excellence, choose the filter that guarantees outstanding filtration, unparalleled durability, and effortless installation. Experience the Difference Today! Join countless satisfied customers who have already experienced the difference with the Kalmar Equipment Filter. Enhance your equipment's performance, protect your investment, and optimize productivity with this exceptional filtration solution. Trust in Kalmar – a name synonymous with innovation, quality, and reliability. Upgrade to the Kalmar Equipment Filter and unlock the full potential of your machinery. Reach new heights of efficiency, reliab...