SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Part Number:03254375 Part Type:Cabin Air Filter Brand:Manitowoc Replacement MOQ:20pcs

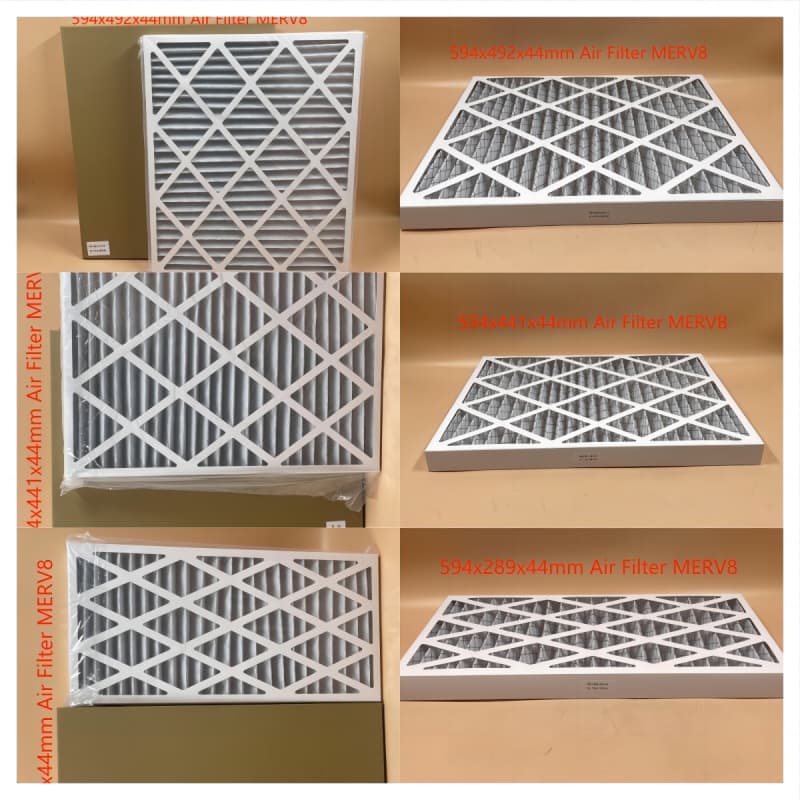

Part Number:6B924 Part Type:Pleated Air Filter MERV Rating:8 Brand:Air Handler Replacement MOQ:20pcs

Part Number:P923075 Part Type:Breather Filter Brand:Donaldson Replacement MOQ:20pcs

Part Type:Water Absorbing ST Filter Brand:Donaldson Replacement MOQ:60pcs

Part Number:SA12195 Part Type:Air Filter Brand:Hifi Replacement MOQ:20pcs SA12195 Air Filter Cross Reference 17211-Z07-000 Use For Honda EU20I EU22I GX100.

Part Number:X773038 Part Type:Urea Filter Kit Brand:Donaldson Replacement MOQ:60pcs X773038 Fuel Filter Cross Reference 2265673 Use For Scania G280 G320 G360 G370 G410 G450.

Dear Valued Customers, Partners, and Colleagues, Warm greetings from CHINA EVERLASTING PARTS CO., LIMITED. Thank you for your long-term trust, cooperation, and continuous support. As the new year approaches, we would like to inform you of our official holiday arrangement for early 2026. Please be kindly noted that our company will observe a three-day holiday from January 1 to January 3, 2026. During this period, our office and factory operations will be temporarily closed. Routine processes such as order handling, production scheduling, and shipment arrangements may experience slight delays. We kindly recommend that you make necessary plans in advance to ensure smooth business operations. Please rest assured that our sales team will remain available online during the holiday and can be reached via email or WhatsApp for inquiries, quotations, and urgent communication.While responses may not be as immediate as on regular working days, we will do our best to support you in a timely and professional manner. All normal business operations will fully resume on January 4, 2026. Any pending matters during the holiday period will be handled promptly upon our return. This holiday allows our team to recharge and return with renewed energy, enabling us to continue delivering high-quality filtration solutions, including air filters, oil filters, fuel filters, hydraulic filters, as well as OEM and ODM customized services for global customers. On this occasion, we would like to extend our sincere best wishes to you and your team. May 2026 bring you good health, smooth cooperation, and continued business success. We look forward to strengthening our partnership and achieving greater growth together. Thank you for your understanding and support. Kind regards, CHINA EVERLASTING PARTS CO., LIMITED Professional High Quality Filters Manufacturer Contact: Email: Sales@filters-king.com WhatsApp/WeChat: +86 18965520297 | +86 18144082725

2025-12-31

2025-12-31Dear Valued Customers, Partners, and Colleagues, Warm greetings from CHINA EVERLASTING PARTS CO., LIMITED. Thank you for your long-term trust, cooperation, and continuous support. As the new year approaches, we would like to inform you of our official holiday arrangement for early 2026. Please be kindly noted that our company will observe a three-day holiday from January 1 to January 3, 2026. During this period, our office and factory operations will be temporarily closed. Routine processes such as order handling, production scheduling, and shipment arrangements may experience slight delays. We kindly recommend that you make necessary plans in advance to ensure smooth business operations. Please rest assured that our sales team will remain available online during the holiday and can be reached via email or WhatsApp for inquiries, quotations, and urgent communication.While responses may not be as immediate as on regular working days, we will do our best to support you in a timely and professional manner. All normal business operations will fully resume on January 4, 2026. Any pending matters during the holiday period will be handled promptly upon our return. This holiday allows our team to recharge and return with renewed energy, enabling us to continue delivering high-quality filtration solutions, including air filters, oil filters, fuel filters, hydraulic filters, as well as OEM and ODM customized services for global customers. On this occasion, we would like to extend our sincere best wishes to you and your team. May 2026 bring you good health, smooth cooperation, and continued business success. We look forward to strengthening our partnership and achieving greater growth together. Thank you for your understanding and support. Kind regards, CHINA EVERLASTING PARTS CO., LIMITED Professional High Quality Filters Manufacturer Contact: Email: Sales@filters-king.com WhatsApp/WeChat: +86 18965520297 | +86 18144082725

2025-12-18

2025-12-18High-efficiency oil filters protect your equipment and engine Use industry-leading oil filtration technology to extend equipment life and improve performance Oil Filter Types Engine Oil Filters For engines, protecting critical components from wear and contamination. Hydraulic Oil Filters Designed for hydraulic systems, high pressure and temperature resistant. Spin-on Oil Filters Easy replacement, commonly used in trucks and construction machinery. Cartridge Oil Filters Eco-friendly, replaceable filter element for reduced waste. Bypass Oil Filters High filtration efficiency, extends main filter life. Oil Filter Brands Find replacement oil filters quickly by brand. Brand Brand Brand Baldwin Pall Caterpillar / Cat Donaldson Parker John Deere Fleetguard Rexroth / Bosch Rexroth Isuzu Hifi / Hifi Filters SF Schupp Kobelco Hydac Stauff Sakura Mahle / Knecht Wix Bobcat MP Filtri Mann / Mann-Filter Claas Why Choose Our Oil Filters? High Efficiency Filtration (3–30µm) Long Lifespan — 1.5–2x Standard Premium Materials: Microfiber & Steel Support ISO9001 / CE Certified OEM & ODM Available Choose the right oil filter for your equipment Excavators Applicable Oil Filters: Glass Fiber, Composite Material Filter Features: High precision filtration to remove fine particles, ensuring the engine remains free from contaminants even in harsh environments like dirt, dust, and heavy-duty operations. Bulldozers Applicable Oil Filters: Glass Fiber, Metal Mesh Filter Features: Filters effectively under high pressure and temperature, capable of removing large contaminants, thus ensuring the engine runs smoothly under heavy loads and reducing wear. Loaders Applicable Oil Filters: Composite Material, Glass Fiber Filter Features: Provides a balance of high filtration efficiency and extended service life, ideal for medium-load environments where oil cleanliness and smooth lubrication are essential. Cranes Applicable Oil Filters: Glass Fiber, Metal Mesh Filter Features: Designed for extreme conditions, these filters offer high filtration performance, preventing impurities in high-temperature, high-pressure environments, which extends the life of the equipment. Agricultural Equipment Applicable Oil Filters: Paper Material, Composite Material Filter Features: Suitable for routine agricultural tasks, these filters offer basic filtration to ensure engine longevity and reduce the maintenance frequency of agricultural machinery. FAQ 1. How do I know which oil filter is suitable for my equipment? To choose the right oil filter for your equipment, consider the type of machinery (e.g., excavators, bulldozers, cranes), the operating conditions (e.g., high temperature, heavy loads), and the type of oil filter material (e.g., glass fiber, composite material). If you’re unsure, you can check the product details on our website, or reach out to our customer support team for guidance. 2. Why is it important to select the right oil filter for my equipment? Using the correct oil filter en...

2025-12-09

2025-12-09Pleated Air Filter: Features Functions and Applications Key Features High Surface Area: Pleated design increases filtration media exposure Enhanced Efficiency: MERV 8-13 ratings capture particles 0.3-10 microns Durable Materials: Synthetic media with moisture resistance Optimized Airflow: Low resistance design reduces energy consumption Performance Comparison Feature Pleated Filter Flat Panel Filter Service Life 3-6 months 1-3 months Dust Holding Capacity High (150-300g/m²) Low (50-100g/m²) Initial Pressure Drop 30-50 Pa 20-30 Pa Primary Functions Pleated air filters serve three critical purposes in air management systems: Particulate Removal: Captures 85-95% of airborne contaminants Allergen Control: Effective against pollen (10-100μm) and pet dander (2.5-10μm) Equipment Protection: Prevents coil fouling in HVAC systems Application Areas Residential HVAC systems Commercial office buildings Healthcare facilities Pharmaceutical cleanrooms Food processing plants Automotive manufacturing Data center cooling systems Laboratory exhaust systems Contact Us WhatsApp/Wechat: +86 18965520297 WhatsApp/Wechat: +86 18144082725 Email: Sales@filters-king.com

2025-09-30

2025-09-30Notice of Mid-Autumn Festival & National Day Holiday Dear Customers and Partners, Please be informed that our company will observe the Mid-Autumn Festival and National Day Holiday from October 1st to October 8th, 2025, for a total of 8 days. Our office will be closed during this period, and normal business operations will resume on October 9th, 2025. However, our sales team will remain available online via email or WhatsApp throughout the holiday. You are welcome to send inquiries at any time, and we will respond as soon as possible. Contact: Email: Sales@filters-king.com WhatsApp/WeChat: +86 18965520297 | +86 18144082725 We appreciate your understanding and wish you a happy Mid-Autumn Festival and National Day! Best regards, CHINA EVERLASTING PARTS CO., LIMITED

2025-08-23

2025-08-23MERV 8 Pleated Medium Efficiency Filters MERV 8 pleated medium efficiency filters are widely used in various air filtration systems due to their excellent performance and cost - effectiveness. These air filters are designed with a MERV (Minimum Efficiency Reporting Value) rating of 8, which means they can effectively capture a wide range of airborne particles. They can trap dust, pollen, mold spores, and even some pet dander, providing cleaner air for indoor environments. The pleated design of these filters increases the surface area, allowing for better airflow while maintaining high filtration efficiency. This design also helps to reduce pressure drop, which means the air can pass through the filter more easily without putting too much strain on the HVAC system. As a result, the energy consumption of the system can be reduced, leading to lower operating costs over time. These air filters are commonly used in residential and commercial HVAC systems, such as central air conditioning and heating units. They are also suitable for some industrial applications where moderate air quality control is required. By using MERV 8 pleated filters, you can improve the indoor air quality, reduce the risk of allergies and respiratory problems, and create a healthier and more comfortable living or working environment. WhatsApp / Wechat: +86 18965520297 WhatsApp / Wechat:+86 18144082725 Email: Sales@filters-king.com

2025-01-28

2025-01-28Company Spring Festival Holiday Announcement Dear All, We are pleased to announce that our company will be observing the Spring Festival holiday from 2025-1-25 until 2025-2-6. The holiday period provides an opportunity for our employees to celebrate and spend quality time with their loved ones during this important traditional festival. During this period, our offices will be closed and regular business operations will be temporarily suspended. We kindly request all employees to plan their work accordingly and ensure that any pending tasks or deadlines are completed before the holiday period begins. We believe that taking time off to relax and recharge is crucial for maintaining a healthy work-life balance. This extended break offers everyone an opportunity to unwind, rejuvenate, and return to work with renewed energy, creativity, and motivation. As always, we encourage our employees to remain mindful of their health and safety during the holiday season. While you enjoy the festivities, please adhere to local health guidelines, practice social distancing, and take necessary precautions to stay safe and healthy. In case of any urgent matters during the holiday period, please contact the designated points of contact provided to you by your department. They will be available to address any critical issues that may arise. We would like to take this opportunity to express our gratitude for your hard work and dedication over the past year. Your contributions and commitment have been invaluable to the success of our company. We wish you all a joyful and prosperous Spring Festival filled with happiness, good fortune, and precious moments spent with your loved ones. Thank you for your attention, and we look forward to seeing everyone back at work on February 7, 2025. Best wishes, Filters-King Our sales Service online by email or WhatsApp during this long holiday, Welcome inquiry anytime. Email:Sales@filters-king.com WhatApp:+8618144082725

2024-12-24

2024-12-24Happy Christmas Merry Christmas to all! On this special day of peace and joy, I would like to take a moment to extend my heartfelt wishes to each and every one of you. May this Christmas be filled with love, warmth, and happiness. As we gather with our loved ones, let us cherish the moments of togetherness and appreciate the blessings that surround us. May the spirit of Christmas bring us closer to one another, fostering a sense of unity and compassion. May your homes be adorned with laughter and merriment, resonating with the sound of joyful carols. May the flickering lights on the Christmas tree illuminate your path with hope and inspiration. During this season of giving, may your hearts overflow with kindness and generosity. May you find joy in sharing with those in need, spreading love and cheer throughout the community. Let us remember the true meaning of Christmas – a time to celebrate the birth of Jesus Christ and the message of love, peace, and hope that He brought to the world. May His teachings guide us in our interactions with others, promoting understanding and acceptance. As we exchange gifts and indulge in festive feasts, let us also remember the importance of gratitude. Take a moment to appreciate the blessings that have been bestowed upon us and express gratitude for the love and support of our family and friends. On this magical night, may your hearts be filled with childlike wonder and excitement. May the spirit of Christmas ignite a flame of joy and contentment that will continue to glow throughout the coming year. Once again, Merry Christmas to all! May this holiday season be a time of joyous celebrations and may the New Year bring abundant blessings, happiness, and fulfillment! In this warm festival, we are still at your service, welcome to consult! Email:Sales@filters-king.com WhatApp:+8618144082725

2024-09-30

2024-09-30Dear Valued Customers, We hope this message finds you well. We are pleased to announce that China Everlasting Parts Co., Limited will be observing the National Day holiday from October 1st to October 7th, 2024. During this period, our offices will be closed for a total of seven days to celebrate the 75th anniversary of the founding of our great nation. We would like to take this opportunity to extend our heartfelt congratulations to our motherland on this momentous occasion. It is a time for us to reflect on the progress and achievements of the past 75 years and to look forward to a future filled with even greater possibilities. We appreciate your understanding and patience during this celebratory time. Should you have any urgent matters that need attention, please feel free to contact our customer service team, and we will do our best to assist you. Warmest regards, China Everlasting Parts Co., Limited Our sales Service online by email or WhatsApp during this long holiday, Welcome inquiry anytime. Email:Sales@filters-king.com WhatApp:+8618144082725