SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

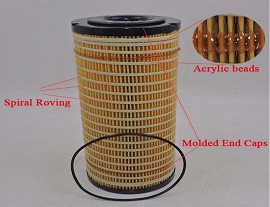

The Fuel Water Separator FBO60364 FBO 60364 FBO Series Replacement Cartridges are designed for use with FBO Filtration Assemblies. They are available as water separators, silicone-treated particle removers, and water-absorbing filters, with ratings of 1, 5, 10, or 25 microns.

The Exhaust Filter RE554498 Cross Reference V837079423 008821335 UF101 8-98169403-0 47364243 21516229 Application For Autocar,Blue Bird,DAF,Ford,Foton,Freightliner,Heuliez,Hino,International,Isuzu,Iveco,Kenworth,Mack,Peterbilt,R.V.I.,Spartan,Solaris,Volvo,Western Star,and Off-Hwy Equipment using Diesel Exhaust Fluid

The Crankcase Ventilation Filter 46595859 400406-00160 Cross Reference 7298180 5288839 CV52055 70024284 600-333-3900 Application For Bobcat,Cummins,Epiroc,Komatsu,Doosan Daewoo Equipment.

The Fuel Water Separator FBO60356 FBO 60356 Coalescer/separator filters are a two stage element that removes water and contaminants from diesel fuel streams and are the most popular filters.

The FBO60329 FBO 60329 FBO Series Replacement Cartridges are designed for use with FBO Filtration Assemblies.They are available as water separators, silicone-treated particle removers, and water-absorbing filters, with ratings of 1,5,10,or 25 microns.

The Air Filter 54107442 Application For Volvo Engine TAD551VE,Konecranes Liftace Forklift F16-600C.

The annual May Day has arrived During the May Day holiday, our will be closed for five days. This, also known as Day, has its origins in the labor movement and is celebrated in countries around the world. The commemorates the achievements and contributions of workers. The history of the May Day holiday dates back to the late 19th century when labor activists around the world began to organize movements advocating for better working conditions, fair wages, and reduced working hours. One significant event that led to the establishment of this holiday was the Haymarket affair, which took place in Chicago, United States, in 1886. The labor movement called for a general strike on May 1st to demand an eight-hour workday. Over time, May 1st became symbolic for workers' rights, and many countries adopted it as a public holiday. In China, the May Day holiday was formally recognized in 1949 and has since been observed nationwide. It provides an opportunity for people to take a break from work, spend time with their families, and engage in leisure activities. In our company, the decision to have a five-day break during the May Day holiday is to allow our employees to rest and recharge. It is also a gesture of appreciation for their hard work and dedication throughout the year. We believe that a well-rested workforce is more productive and motivated, and this holiday serves as a way to promote work-life balance. During the May Day holiday, our company encourages employees to enjoy their time off responsibly, engage in recreational activities, or use the time for personal pursuits. We hope that this break will provide our employees with the opportunity to rejuvenate and return to work with renewed energy and enthusiasm. Our sales Service online by email or WhatsApp during this long holiday, Welcome inquiry anytime. Email:Sales@filters-king.com WhatApp:+8618144082725

2019-08-03

2019-08-03Engine air filters are developed based on filter performance requirements, vehicle operating environment, available space, filter media characteristics and production techniques. The design process includes analytical theory and empirical models describing the filter media properties and aerosol flow in the filter housing as well as the filter elements. Filter media carefully based on these models and simplified laboratory testing. The filter design was evaluated in great detail through a series of laboratory and field experiments. The role of the engine intake system has increased due to engine exhaust particulates and evaporative emission regulations. Engine life, engine emissions and fuel consumption depend on the design of the intake system and its performance. Providing an optimized solution to these requirements determines the trend of the filter. This has driven the need for smaller, more compact filters and more efficient permeability filter media. The efficiency can be significantly improved by applying a layer of nanofibers to the cellulose or synthetic substrate. The ISO fractional efficiency test method, in its final development stage, clearly shows the advantages of nanofiber filter media. The ISO fractional efficiency test method, in its final development stage, clearly shows the advantages of nanofiber filter media.

2019-07-26

2019-07-26The structure of the filter material can be divided into two types: surface type and depth type. (1) surface type The surface type filter material is a fine filter mesh woven with a wire, and is also used in other forms such as wire winding. The filtration accuracy is determined by the size of the woven holes or the size of the wire gap. Any particles larger than the size or clearance of the aperture can not pass through just the ideal state, which is not practical in practice. The woven filter or wire is wound into a filter element having the same size of pores, and its filtering action only occurs on the surface of the filter screen, so it is called surface type filtration. As the dirt accumulates on the surface of the screen, its pores are constantly blocked, so that the pressure drop is gradually increased; the filtration efficiency is also lowered because the particles trapped in the mesh may be squeezed out of the mesh at any time. If it is desired to control the pressure drop within a certain range, the filter element should have a sufficiently large filtration area. This filter element can be reused after cleaning. (2) Deep filter media The deep filter media is made of fiber papermaking and has a certain thickness of filter media. The properties of this filter are quite different from those of surface type filtration. Its shape of the eyelet, the size is irregular, uneven, and the inner part is complicated by bending and twisting. Its filtering effect occurs not only on the surface of the filter medium but also in the depth of the filter medium, so it is called depth type filtration. Since the filter medium has a certain thickness and the passage is in all directions, its dirt holding capacity is much larger than that of the surface type filter, and the pressure drop is also much lower than that of the surface type filter. In addition, because of its wide range of pore size distribution, it can also filter out a large number of fine particles. For the depth filter, the fiber diameter constituting the filter medium has a direct influence on the filtration efficiency and other properties. A filter layer made of a relatively small diameter fiber can form more through holes in a unit area, and can also form more channels in the interior. Therefore, its filtration efficiency and dirt holding capacity are higher than those of the coarser fiber. For the same reason, its pressure drop is also smaller than the latter. Therefore, the filter element made of fine fiber has a long working life.

2019-07-12

2019-07-12One: start inspection and preparation 1: Before using the water separator equipment, the driver's consent should be obtained. 2: Check the line installation of the fuel water separator, whether the steering of the supporting pump is normal 3: Water is supplied to the fuel water separator, and the top air valve is opened to allow air to escape. 4: Check the oil and water separation in the marrow water inlet and outlet system without any leakage Two: precautions during operation 1: Adjust the drain valve opening degree and keep the pressure inside the separator to facilitate the elimination of the oil in the separator. 2: Observe whether the gauges such as pressure gauges and thermometers are normal. 3: Observe the working condition of the treated drainage water quality and oil concentration alarm 4: After the discharge is over, it should continue to be poured into clean water for 15 minutes to clean the separator. 5: Close the inlet and outlet after the pump is stopped, avoid the loss of clean water in the cylinder, reduce the oxidation and corrosion of the inner wall. 6: Each time the fuel water separator is used for discharge, it should be recorded in the oil beauty record book. Three: maintenance 1: Regularly clean the filter, open the bottom of the separator to vent, and remove the sediment deposited in the lower part, impurities 2: Clean the internal separation components of the separator in time, and avoid cleaning the inner wall and components of the separator with a cleaning agent. 3: When a fault occurs, the cause should be identified and the failed coalescing component should be replaced in time.

2019-07-05

2019-07-05Second Big Discount Sale during 1th, July,2019 to 31th, July,2019 CH10929 $6.00USD/PC MOQ 200PCS CH10930 $6.00USD/PC MOQ 200PCS CH10931 $6.00USD/PC MOQ 200PCS

2019-06-28

2019-06-28An air filter is a device that purifies air. The air filter removes suspended particulate matter from the air entering the cylinder to reduce the wear of the cylinder and piston and piston ring to extend the life of the component. The air filter is a consumable item and is usually replaced once every 10,000 kilometers. The main requirements of the air conditioner are high filtration efficiency, low flow resistance, and continuous use for a long time without maintenance. · It is important to choose the right filter. Why do you say this? The main reason is that the bacteria dust in the summer air is abnormally active, and in other weathers, the filter may not feel anything, but the filter that is not suitable in summer will Shows the problem, because if you have pollen allergies and don't choose pollen filters or filters that filter well, then you are likely to be miserable while driving, and the summer air filter is better. For the protection of the body, pay special attention to the more hair, and a good filter can filter a lot of hair and dust, because the summer dry explosion often the road dust will float so good filter for summer road dust filter It is very good.

2019-06-21

2019-06-21In the past, the PL420 was used as the first primary filter for the fuel tank girders. There is no pressure. The common rail is pressurized, and the PL420 is under negative pressure. Before the appearance of the electronic pressure pump, the transparent cup is very safe, there is no pressure damage to the transparent cup, but with the advent of the electronic pressure pump, the engine's two coarse filters change from negative pressure to 4 positive pressures or even greater pressure. The old-fashioned PL420 transparent cup has the risk of oil leakage. Some OEMs changed the PL420 on the engine to the PL421 without a cup. However, some OEMs did not consider this problem. They still loaded the PL420. (There are now Delong) there are design risks. It is recommended to use the filter PL421 for models equipped with an electronic pump. Filters PL420 and PL421, we can provide, if you need, please feel free to contact us.

2019-06-19

2019-06-19Good news, filters 328-21600, 751-10620, FGO803, FHU801. Free of charge within 3PCS. But you have to bear the freight. If you have need exceed 100pcs, we can give you a big discount, Until they're sold out. If you are interested in these filters, please feel free contact us by the following way: Email:Sales@filters-king.com WhatsApp:+8618144082725 Wechat:+8618144082725 Skype:Filters-king

2019-06-06

2019-06-06We will meet Dragon Boat Festival from June 7st, 2019 to June 9th, 2019. Our warehouse will be closed from June 7st, 2019 to June 9th, 2019. I can't send products during this holidays, I hope you understand. During the holidays, if you have any need filters, please leave message or add my WhatsApp/wechat +8618144082725. I will reply you in the first time.