SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

The Oil Filter 22030852 Cross Reference LF16367 WP962/5 SO11094 SP96039 Application For Volvo Penta D4 & D6 Series.

The Fuel Water Separator 3809721 Application For Volvo-Penta Marine D11A-C,D11A-CMP,D11A-D,D11A-DMP,D11A-E.

The Oil Filter 8692305 Cross Reference 1421704 CH9954 OX370D 25.039.00 HU719/8X WL7320 Application For Volvo Automotive.

The Oil Filter 3840525 Cross Reference 332145564 15601-87104 LF17532 96058042 16510-83011 Application For GMC Imports,Suzuki Automotive.

The Air Filter 800155718 Cross Reference 11822829 11K921310 60C1561 SA16994 SL83073 Application For Hyundai HX 300A L.John Deere 544G,644G,WL430,WL53,WL56.Liebherr R934,R938,R938C.

Customized oil and gas separator, providing dimensions or samples, produced according to your requirements.

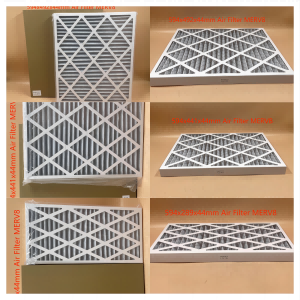

Introducing the Pleated Medium Efficiency Filter - a cutting-edge solution designed to revolutionize filtration in ventilation systems. Crafted with utmost precision and innovation, this advanced filter sets new benchmarks in performance and reliability. With its unrivaled efficiency, the Pleated Medium Efficiency Filter effectively removes contaminants, pollutants, and particulate matter from the air, ensuring clean and healthy environment. By trapping even the tiniest particles, this filter safeguards your space from harmful substances, enhancing the overall air quality. Engineered to excel in diverse application fields, the Pleated Medium Efficiency Filter finds its utility in electronics, pharmaceuticals, mechanical instruments, metallurgy, petroleum, chemical industry, light industry, food, and more. Versatile and adaptable, it adapts seamlessly to various industrial settings, providing unparalleled filtration capabilities. The exceptional design of this filter features pleated technology, allowing for an expanded surface area that maximizes filtration efficiency. This innovative fold design not only enhances performance but also extends the filter's lifespan, reducing maintenance costs and ensuring optimal functionality for an extended period. Uncompromising on quality, the Pleated Medium Efficiency Filter undergoes rigorous testing and adheres to stringent industry standards to deliver unmatched reliability. With seamless integration into ventilation systems, it guarantees a seamless and hassle-free filtration experience. Invest in the Pleated Medium Efficiency Filter today and experience the epitome of air filtration technology. Breathe in the pristine air, free from impurities, and enjoy a healthier, cleaner environment. Trust in its efficiency, trust in its performance - it's time to elevate your filtration game like never before. Note: The word count may vary slightly depending on formatting.

2019-07-26

2019-07-26The structure of the filter material can be divided into two types: surface type and depth type.

(1) surface type

The surface type filter material is a fine filter mesh woven with a wire, and is also used in other forms such as wire winding. The filtration accuracy is determined by the size of the woven holes or the size of the wire gap. Any particles larger than the size or clearance of the aperture can not pass through just the ideal state, which is not practical in practice. The woven filter or wire is wound into a filter element having the same size of pores, and its filtering action only occurs on the surface of the filter screen, so it is called surface type filtration. As the dirt accumulates on the surface of the screen, its pores are constantly blocked, so that the pressure drop is gradually increased; the filtration efficiency is also lowered because the particles trapped in the mesh may be squeezed out of the mesh at any time. If it is desired to control the pressure drop within a certain range, the filter element should have a sufficiently large filtration area. This filter element can be reused after cleaning.

(2) Deep filter media

The deep filter media is made of fiber papermaking and has a certain thickness of filter media. The properties of this filter are quite different from those of surface type filtration. Its shape of the eyelet, the size is irregular, uneven, and the inner part is complicated by bending and twisting. Its filtering effect occurs not only on the surface of the filter medium but also in the depth of the filter medium, so it is called depth type filtration. Since the filter medium has a certain thickness and the passage is in all directions, its dirt holding capacity is much larger than that of the surface type filter, and the pressure drop is also much lower than that of the surface type filter. In addition, because of its wide range of pore size distribution, it can also filter out a large number of fine particles.

For the depth filter, the fiber diameter constituting the filter medium has a direct influence on the filtration efficiency and other properties. A filter layer made of a relatively small diameter fiber can form more through holes in a unit area, and can also form more channels in the interior. Therefore, its filtration efficiency and dirt holding capacity are higher than those of the coarser fiber. For the same reason, its pressure drop is also smaller than the latter. Therefore, the filter element made of fine fiber has a long working life.