SIGN UP TO OUR EMAIL NEWSLETTER

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

The Crankcase Breather Filter 3584145 Cross Reference CV50841 RE546466 65.01804-7005 LC5001X Application For Atlas Copco,Cummins Power Generation,John Deere,Sdmo,VOLVO-PENTA Marine Equipment.

The Transmission Oil Filter 3312199031 3312301037 Cross Reference 3582069 35815419 SH62357 HY90491 Application For Volvo Penta B4-180BBT,ZF 25/25A BV/Gearbox,45A/45-1 BV/Gearbox,80A BV/Gearbox,HSW250A BV/Gearbox,HSW450A BV/Gearbox,HSW630H BV/Gearbox,HSW800A-3 BV/Gearbox.

The Fuel Water Separator 3332364 333-2364 Cross Reference BF1296-O P551034 K1006520 FS19907 PL270 R270PL Application For Camox,Ingersoll Rand,Terex,Doosan Daewoo Equipment.

The Fuel Water Separator FBO60364 FBO 60364 FBO Series Replacement Cartridges are designed for use with FBO Filtration Assemblies. They are available as water separators, silicone-treated particle removers, and water-absorbing filters, with ratings of 1, 5, 10, or 25 microns.

The Exhaust Filter RE554498 Cross Reference V837079423 008821335 UF101 8-98169403-0 47364243 21516229 Application For Autocar,Blue Bird,DAF,Ford,Foton,Freightliner,Heuliez,Hino,International,Isuzu,Iveco,Kenworth,Mack,Peterbilt,R.V.I.,Spartan,Solaris,Volvo,Western Star,and Off-Hwy Equipment using Diesel Exhaust Fluid

The Crankcase Ventilation Filter 46595859 400406-00160 Cross Reference 7298180 5288839 CV52055 70024284 600-333-3900 Application For Bobcat,Cummins,Epiroc,Komatsu,Doosan Daewoo Equipment.

The annual May Day has arrived During the May Day holiday, our will be closed for five days. This, also known as Day, has its origins in the labor movement and is celebrated in countries around the world. The commemorates the achievements and contributions of workers. The history of the May Day holiday dates back to the late 19th century when labor activists around the world began to organize movements advocating for better working conditions, fair wages, and reduced working hours. One significant event that led to the establishment of this holiday was the Haymarket affair, which took place in Chicago, United States, in 1886. The labor movement called for a general strike on May 1st to demand an eight-hour workday. Over time, May 1st became symbolic for workers' rights, and many countries adopted it as a public holiday. In China, the May Day holiday was formally recognized in 1949 and has since been observed nationwide. It provides an opportunity for people to take a break from work, spend time with their families, and engage in leisure activities. In our company, the decision to have a five-day break during the May Day holiday is to allow our employees to rest and recharge. It is also a gesture of appreciation for their hard work and dedication throughout the year. We believe that a well-rested workforce is more productive and motivated, and this holiday serves as a way to promote work-life balance. During the May Day holiday, our company encourages employees to enjoy their time off responsibly, engage in recreational activities, or use the time for personal pursuits. We hope that this break will provide our employees with the opportunity to rejuvenate and return to work with renewed energy and enthusiasm. Our sales Service online by email or WhatsApp during this long holiday, Welcome inquiry anytime. Email:Sales@filters-king.com WhatApp:+8618144082725

2019-05-31

2019-05-31What are the effects of fuel filter replacement and non-replacement? Gasoline filtration is one of the common filter products, the main function is to remove impurities from gasoline. If the fuel filter is too dirty or blocked, the main performance is: when the fuel is added, the power is slower, or it can't get up, the car is difficult to start, sometimes it takes 2-5 times to catch the fire. Most engines are equipped with disposable, non-removable paper filter fuel filters. The replacement cycle is generally 10,000 kilometers. If you add less gasoline, it is not a problem to replace one with 15000-20000 kilometers. The filter has an inlet and outlet arrow mark, and should not be reversed when replacing. The fuel filter is to filter the impurities in the gasoline you usually add. It takes a long time. Your fuel filter is full of dirt, dirt and dregs. Therefore, it is recommended to change the number of kilometers. If you don't change it, or delay the change, it will definitely affect the performance of your car; for example, the oil road is not smooth, the car is not motivated, the time is long, the filter performance of the steam filter is greatly reduced, and finally the engine is damaged chronically, and even the engine is overhauled. If you don't change it, it will definitely bring a lot of damage to the car.

2019-05-18

2019-05-18In the dust collector, the cloth bag is an important part, which mainly plays the role of filtering and collecting dust and debris to achieve purification. The cleaning, maintenance and replacement of the bag of the dust collector are as follows. 1. Cleaning of the bag: Cleaning: Select the appropriate washing materials, after strict ratio, and the cleaning strength should be moderate, the strength is too small, the cleaning is not thorough, and the lightness will cause damage to the bag. Repair: If the bag is worn or corroded, it needs to be repaired to ensure that the bag can be used normally. However, if the situation is serious, professionals who require air handling equipment recommend replacing the bag. Cleaning: By vibrating, the large dust particles in the bag are removed to maintain the filtration performance. Drug soaking: It is the use of some chemical agents to remove oil stains or dirt that cannot be washed with water in order to increase the breathability of the bag. Drying: Dry the bag with hot air at a temperature of 110 degrees Celsius. After the bag is dried, it must be guaranteed not to deform and retract. Quality inspection packaging: After the cloth bag has been cleaned, it must undergo strict quality inspection. After the test is qualified, it can be packaged and affixed with a certificate. 2. Maintenance of the bag If the bag is damaged, stop working immediately and repair it. If it is just a small hole, it can be bonded using a silicone rubber compound at the breakage. When selecting a binder, be aware that it should be compatible with the temperature, chemical properties, and process of the bag, otherwise problems may occur. 3. Bag replacement If the bag is damaged seriously, or if a lot of tiny dust accumulates inside it, the cleaning effect is not ideal, and it has affected the use of the bag, it must be replaced. It is not necessary to stop the dust collector when replacing. Just turn off the cleaning controller and open the manhole door to replace it. After installing a new bag, clean it around.

2019-04-30

2019-04-30The three factors that directly affect the service life of the hydraulic oil filter, the service life of the filter element in the hydraulic system is an important problem of the actual hydraulic system, especially in the case of high pollution conditions, the failure of the filter element and the resulting hydraulic system The fault is particularly prominent. There are three main factors that affect the life of a hydraulic filter: First, hydraulic oil filter filtration performance Filtration Accuracy: Filtration accuracy refers to the ability of the filter material to filter out particulate contaminants of different sizes. It is generally considered that the filtration precision is high and the life of the filter element is short. Second, the amount of pollution The amount of pollutants refers to the weight of particles contaminated by the filter material per unit area when the pressure drop of the filter material reaches a specified amount during the test. The filter element hole is easily retained by the accumulation of particulate contaminants through the channel, so that the pressure difference is increased, and when the pressure difference reaches the specified maximum limit value, the service life is terminated. The most direct parameter of the end of the filter life is that the pressure difference between the upstream and the downstream of the filter element reaches the pressure at which the bypass valve is opened. At this time, the dirt holding capacity of the filter element also reaches the maximum value. If the filter element is designed and manufactured, consider increasing the filter element. The ability to foul, that is, to improve the life of the filter. 1, wave height, wave number and filter area Under the premise that the outer dimensions of the filter element have been determined! Change the wave height, wave number and other process parameters to increase the effective filter area ofthe filter material as much as possible, which can reduce the flux of the unit filter surface and increase the dirt absorption of the whole filter element, and improve the filter life. By increasing the filter area ofthe filter element, the life of the filter element increases more often. If the wave number increases too much, the crowded folding wave will reduce the flow space of the hydraulic oil between the wave and the wave, so that the pressure difference of the filter element increases! The time difference of the differential pressure alarm is short and the life is reduced. It is generally preferred to keep the wave spacing between 1.5 and 2.5 mm. 2, the strength of the support network It is very important that the wire mesh of the inner and outer layers in the filter element structure has a certain strength. The wire mesh maintains the pleat shape to prevent bending and supports the filter material to prevent fatigue failure. Third, the pollution status of the hydraulic fluid during the use of the filter element After the filter element is ma...

2019-04-01

2019-04-01A good and reliable filter has very high filtration requirements: 1. High filtration accuracy: Filter out all the larger particles (>1 - 2 um) 2. High filtration efficiency: reduce the amount of particles passing through the filter. 3. Prevent early wear on the engine. Prevent damage to the air flow meter! 4. The pressure difference is low to ensure that the engine has the best air-fuel ratio. Reduce filtration losses. 5. Large filtration area, high ash content and long service life. Reduce operating expenses. 6. The installation space is small and compact. 7. The wetness is high, preventing the filter element from sucking, causing the filter element to be broken down. 8. Flame retardant 9. Sealing performance is reliable 10. Good value for money 11. No metal structure. Conducive to environmental protection, can be reused. Conducive to storage. We are good at supply filters for Fleetguard, Caterpillar, Donaldson, Komatsu, Deutz, Perkins, Volvo, Mitsubishi, Iveco, John Deere, FG wilson, Mann, Kobelco, Parker Racor, Hyundai, JCB, Hengst...

2019-03-30

2019-03-30The air filter is directly related to the engine's air intake problem during driving. If the vehicle is only driving in the city, the air filter will not block, but if the car is driving on a dusty road, it needs Pay special attention to the cleaning problem of the air filter. If the air filter is clogged or the dust is too much, the engine intake will be poor, and a large amount of dust will enter the cylinder, which will accelerate the cylinder carbon deposition speed, make the engine ignite poorly, and the power is insufficient. The fuel consumption of the vehicle will naturally Raise. If you are driving on a normal city road, the air filter should be inspected when the car is driving for 5,000 km. If there is too much dust on the filter, consider using compressed air to blow from the inside of the filter to blow off the dust. . However, the pressure of the compressed air should not be too high to prevent the filter paper from being damaged. Do not use water or oil when cleaning the air filter to prevent the oil from immersing the filter element.

2019-02-28

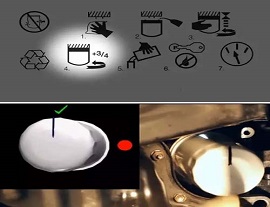

2019-02-28You can't casual find tool to install your oil filter, or install the oil filter directly with your hand. But in reality, some people will do this, if you do, then it is wrong! Delphi fast repair chain professional maintenance workers said: spin-on machine filter (with iron shell) must not be screwed with tools, can not be screwed too tight! The reasons are as follows: First, can't be too tight The sealing ring will be easily folded due to the installation of the filter too tight, and the gap between the sealing ring and the base will be generated and the oil will leak. Second, you can not use tools casually During the installation process, the tool metal should be prevented from being squeezed into the machine filter shell, and the iron sheet is easily thinned. After the iron sheet is thinned, it is prone to bursting during high temperature and high pressure oil operation, which is very dangerous. Note: It is not uncommon for various well-known brand machine filters to cause machine filter bursting, oil leakage and oil leakage under wrong installation. The times are different, efficiency is king, and safety is emphasized. Even if it is a small machine filter, the professional tools are indispensable, and the standard movement of the car repair can not be ignored. Third, there are two kinds of screwing filter methods: 1. Direct hand; 2. Professional set tool In actual work, there are not many vehicles that can be installed by hand, and most of them use the kit tool, as shown below: (Oil filter set) Fourth, use the standard installation actions: 1. Check if the oil filter has bumps. 2. The oil that is refreshed on the seal ring. 3. Rotate the filter by hand until the filter ring is in contact with the base (that is, when you start pushing). 4. Rotate 3/4 more turns (marked with a dash).

2019-02-26

2019-02-26Precision automotive filters are the most common configuration in air compressor systems and are inexpensive but critical to air compressor systems. China Everlasting Parts Co., Ltd. is a filter manufacturer, including precision automotive filters, oil filters, fuel filters, hydraulic filters, air filters, Fuel water separator, filter cartridges and other products. Regardless of the type of filter, a filter element is required, which is the core of the filter. Precision automotive filters are an important component of air compressors and air purifiers. More and more companies are paying attention to the precision automotive filter industry and are widely welcomed by consumers. At present, the construction of precision automotive filters is generally composed of filter paper and rubber, and the true and false glue is also different. The authentic rubber has a good texture and elasticity, while the fake rubber is soft and has a poor texture. The easier way to distinguish is to fold the filter paper in half. After the loosening, the genuine product will quickly return to its original state, and the counterfeit is not well bonded to the filter paper due to the rubber texture problem.

2019-02-22

2019-02-22Maintenance of hydraulic oil filter: 1. Before replacing, first remove the original hydraulic oil, check the oil return filter, oil absorption filter, and pilot filter to see if iron, copper scrap or other impurities are attached, and remove impurities and clean them in time. 2. If you need to replace the hydraulic oil filter, you need to replace it all, otherwise it is equivalent to white replacement. 3, to learn to identify the hydraulic oil label, different brands, different brands of hydraulic oil can not be mixed, so as not to affect the use. 3. Install the oil suction filter before refueling to prevent impurities from entering. 5. The general fuel tank has an oil level gauge, which should be added to the standard position when refueling. When the refueling is completed, pay attention to exhausting the main pump. Otherwise, the whole vehicle cannot be started temporarily, and the main air pump is damaged by the air pocket.